Seite 3 von 20

Re: Dismantling and repairing the motor :o

Verfasst: Fr 24. Jan 2025, 20:50

von bob2.0

The motor is dismounted and I have strapped it to my fold-up work table.

I have removed the screws and installed guide-bolts.

My hydraulic jack fits perfectly so I can push it up from below.

Photos available, but can I first ask, what is the way to break off the cover plate?

The sealant is very solid. I have tried cutting into it with a metal foil I have for taking mobile phones apart, but just can't get into the gap. The aluminum looks very soft, I have already scratched it, barely trying.

How have people broken through the sealant and separated the cover plate?

Re: Dismantling and repairing the motor :o

Verfasst: Fr 24. Jan 2025, 22:00

von MEroller

I just dug with an old knife blade into the gap between lid and rim, and massaged it open, but my erider motor probably did not have as much sealant in there, than what you are experiencing. But a heat gun might be able to soften the goo in there, to make prying open the lid easier.

Re: Dismantling and repairing the motor :o

Verfasst: Fr 24. Jan 2025, 22:35

von bob2.0

MEroller hat geschrieben: Fr 24. Jan 2025, 22:00

I just dug with an old knife blade into the gap between lid and rim, and massaged it open, but my erider motor probably did not have as much sealant in there, than what you are experiencing. But a heat gun might be able to soften the goo in there, to make prying open the lid easier.

I was thinking to go with the heat gun, but it was getting cold, so left it for the day and to have a think about getting into the gap.

The problem is that it is close to the rim, so not an easy line to get something in.

A knife is probably the tool, but I will likely have to sacrifice a sharp one for that task. I'll probably start with a Stanley knife blade, on its own and lever it in, as I can get that in the space.

Re: Dismantling and repairing the motor :o

Verfasst: Fr 24. Jan 2025, 22:43

von bob2.0

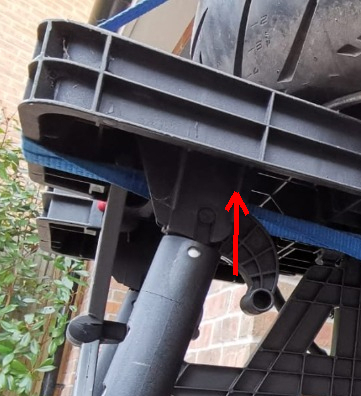

I hope this plan works!

Guide bolts fitted in place of the fixing bolts.

A jack pushing up on the axle.

More importantly is to see if this works, so I can do the reverse when I replace the stator. I want to control it as it gets sucked in to the motor.

Re: Dismantling and repairing the motor :o

Verfasst: Sa 25. Jan 2025, 09:45

von jeff-jordan

Don't know.... will it work with this platform when the force of the jack moves the legs out of their seats?

- platform.jpg (126.66 KiB) 1872 mal betrachtet

Re: Dismantling and repairing the motor :o

Verfasst: Sa 25. Jan 2025, 10:28

von bob2.0

jeff-jordan hat geschrieben: Sa 25. Jan 2025, 09:45

Don't know.... will it work with this platform when the force of the jack moves the legs out of their seats?

Good question.

Thanks for thinking it through with me.

I wasn't expecting that much force, once the stator is finally coming out, but I don't know, so thanks for that. I will strap that up too. Easy to do.

Re: Dismantling and repairing the motor :o

Verfasst: Sa 25. Jan 2025, 11:52

von MEroller

The force can easily approach the region of >500kg for getting the stator moving! I set it on the ground with the to be pushed out axle resting on the concrete floor. Then with all my weight (>100kg) I stepped on the rim side resting on the ground, and with other leg I JUMPED on the side in the air. That was just marginally enough to push the stator out enough so I could grab the other axle (with the nuts on it) and finally pull it out...

Re: Dismantling and repairing the motor :o

Verfasst: Sa 25. Jan 2025, 12:34

von bob2.0

MEroller hat geschrieben: Sa 25. Jan 2025, 11:52

The force can easily approach the region of >500kg for getting the stator moving! I set it on the ground with the to be pushed out axle resting on the concrete floor. Then with all my weight (>100kg) I stepped on the rim side resting on the ground, and with other leg I JUMPED on the side in the air. That was just marginally enough to push the stator out enough so I could grab the other axle (with the nuts on it) and finally pull it out...

OK, thanks, I'll bear it in mind. If things start bending and creaking then I might abort.

How did you get it back in?!

Ah! For the joys of maintenance if they were switched reluctance motors!

Re: Dismantling and repairing the motor :o

Verfasst: Sa 25. Jan 2025, 14:02

von MEroller

The reverse: placing the rim on the ground, setting in the rotor while standing on the rim, but of course the acceleration inwards I could only brake a little, the bearing however did survive the blow. So for inserting a more controlled method should be preferred...

Re: Dismantling and repairing the motor :o

Verfasst: Sa 25. Jan 2025, 14:15

von TwisterMax

Hi Bob,

why don't you look at the photos that jeff-jordan linked to you on the first page? The cover is connected to the motor. With a puller you can simply push the stator out.